Sheet metal tool tray.

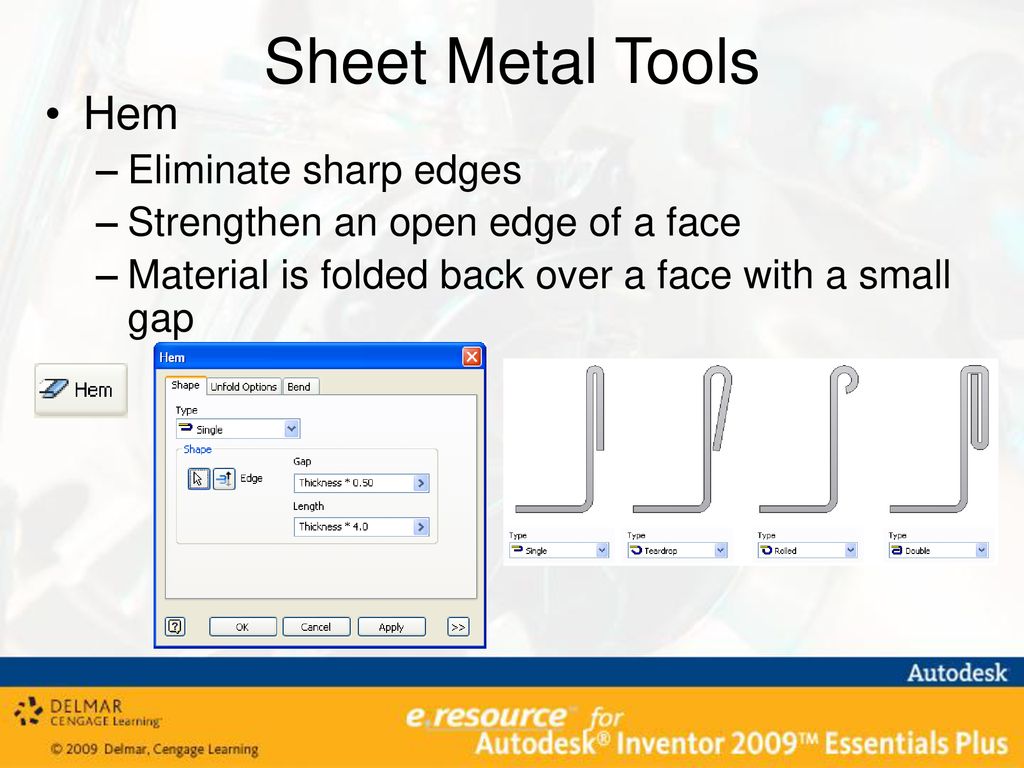

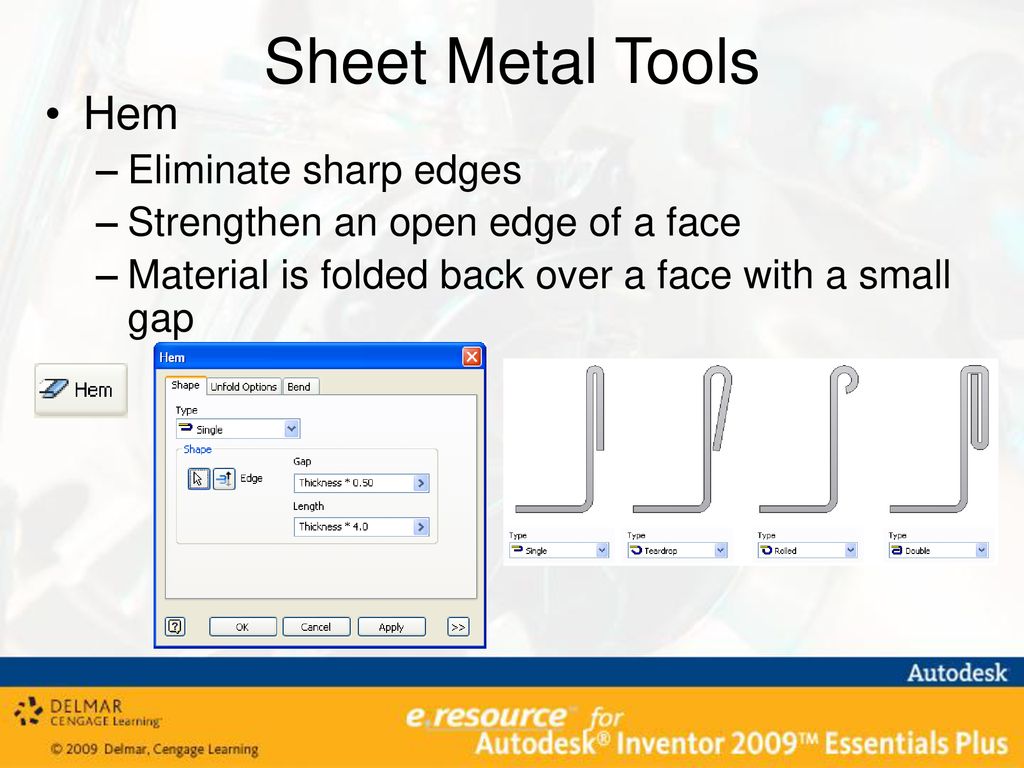

Making sheet metal hems.

Two stage hemming punch and die combination.

Mittler brothers roll sets hem step roll instructional how to tutorial overview duration.

Closed hems are basically flat with the material folded over completely on itself.

Hems are commonly used to reinforce an edge hide burrs and rough edges and improve appearance.

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself.

Hems are created when you fold over the metal back onto itself.

The simplest form of hemming set up is combining two different.

That s why we love it.

Sheet metal hems multi tool setup acute tooling and flattening die.

I like to make stuff 1 189 153 views.

This is putting a simple hem on a curved piece of zinc with a 7ft radius.

They are used to strengthen part edges.

Hemming is the process in which the edge is rolled flush to itself while a seam joins the edges of two materials.

A two stage hemming die works by using a deep channeled die and an acute.

This is the first multiple part project my students work with in class that they will have to assemble together.

It saves time less de burring gives a more finished look to your edges and most importantly it adds tremendous amounts of strength to a face.

The hem tool adds a hem to your sheet metal part at a selected edge.

The grooved seam joint fig.

A hem is basically just bending over the edge of sheet metal to get a smooth finished edge versus a rough or sharp edge hems also help to improve the strength of the sheet metal edge there are several types of hems that solidworks can create and if done correctly features like piano hinges can be built into your part this does take some special tooling so make sure the shop you re working with has the tooling.

Sheet metal in a flat sheet is not very sturdy.

Step 10 repeat the last step again but this time try a different type of hem.

It can be bent warped and folded easily.

An open hem is one that forms a u or c shape and might be used to accept a pin for a hinge.

How to make a diy sheet metal brake duration.

When making a grooved seam on a cylinder you fit the piece over a stake and lock it with the hand groover fig.

It consists of two folded edges that are locked together with a hand groover fig.

2 57 is one of the most widely used methods for joining light and medium gauge sheet metal.

This is the last sheet metal project i assign in my level one manufacturing class.

But when you re designing a sheet metal part add a few strength enhancing features to make sure your part lasts for generations.

Bend a flange all the way over and you have a hem.

Three stage hemming punch and die.